Tech and environment star at the 40th IPM Horti Expo

By John Fitzsimmons

This year marked the 40th Anniversary of the IPM Essen horticultural expo in Germany. It hosted 1400 specialist exhibitors from 14 countries presenting over a massive 100,000m² and 10 exhibition halls. Technology that enhances efficient greenlife production, especially innovations that improve productivity and respond to environmental challenges, were again a feature. They were complemented by the usual new wave of greenlife innovations which is always engaging.

I have attended IPM Essen previously and I definitely know I was not the only Aussie there. More should make the trip and extend their visit across Europe to the many centres of innovation and new applications, if not to identify possible new technologies and equipment, then to accumulate the huge volumes of inspiration and creativity that are present. This report, however, was compiled at distance, but for those inspired by the possibilities another event, GreenTech will be held at the RAI Amsterdam (Netherlands) from 11-13 June 2024, which leaves a comfortable window for planning.

Air

Of the many innovations presented at Essen, that of ‘vertical airflow’ grabbed the attention. First introduced in 2018 by Dutch company Logiqs, this concept can be incorporated in rolling or other grow benches. Originally intended for growing lettuce in vertical farms it has evolved and been successfully applied to growing bromeliads.

Dutch grower LKP and greenhouse builder van der Hoeven took two years to optimise designs and install the idea in a new 1.5 ha greenhouse consisting of three growing departments and four test areas. The result has been “a very homogeneous climate in all departments and requested changes in climate are achieved within minutes”. The result is more growth and energy saving, and a very even production.

In concept ‘vertical airflow’ can be thought of as like the old-school air hockey tables. Plants stand on finely perforated tiles that sit on an air and water-proof insert. Air is forced into the gap under the tiles into what is effectively a manifold to equalise pressure. The design is such that water (nutrient solution) cannot enter the air supply channels, nor can pots or trays block the air outlets. It can be used with various irrigation systems including ebb & flow.

The vertical airflow created is said to create a more desirable temperature and humidity environment from the plants’ lower leaves upwards, and a more even temperature and humidity gradient up through the plants. One effect is said to be the plant’s stomata are kept open, resulting in higher CO2 uptake and higher photosynthesis. Other outcomes can include reduced disease risks and reduced energy costs in the greenhouse.

Benches can be up to 8 m long and 600 mm to 2 m wide. Air speed up through the plants can range from 5 to 50 mm/second. The water level above the tiles (e.g. for ebb & flow) can be as much as +30 mm.

Lighting

Unsurprisingly, a number of advances in grow lighting technologies were also unveiled at the expo.

One example, Growlight FLORAPXL, also from Logiqs, provides a wide beam angle said to result in homogeneous light at a relatively small distance from the plants.

With flexible settings, blue, white, red and far-red can be set independently and each FLORAPXL can be controlled individually. Dimming is practically analogue.

Custom light recipes for each growth phase of the plant can be used and lighting can be optimised for each growing surface.

The suppliers summarise the main advantage, compared to other light solutions, is the relative ease to get the light homogeneous by placing the pixels on the right spot.

Climalux focuses on the development and production of high-quality supplemental full-LED lighting systems for vegetable and ornamental crops based on ‘plant empowerment’, in which energy-efficient growing and optimal production are key concepts. The new CLX V1000 grow light is composed of a dimmable LED-lighting unit and a vertical ventilation system, which distributes heat and moisture evenly in a greenhouse.

The unit is described as creating a microclimate around each plant caused by the vertical air movement in combination with the adjustable light intensity. By properly linking the LED-lamps in a total system, they form a cluster of climate cells that contributes to climate uniformity throughout the greenhouse and “considerable” cost savings – up to 35%.

The spectrum of the CLX V1000 grow light includes green light which, combined with red and blue light, results in a balanced and healthy growth of the crop. The combination leads to white daylight in the greenhouse. The green part of the spectrum causes a greater penetration depth of light, especially in the top of the plant, resulting in intense photosynthesis deep in the leaf and canopy, resulting in a higher crop yield, according to Climalux.

The CultiMesh wireless mesh platform presented at Essen is described as “your next step towards autonomous growing”. This ‘food autonomy lighting’ is said to answer the needs to control luminaires easily and quickly with an affordable wireless solution beyond being a wireless dimming system for lighting fixtures. It is described as “a high-tech, two-way communication platform that creates an indoor, high-precision positioning system that is opening new possibilities in dynamic lighting and other automated greenhouse operations”.

Benefits are said to include it being a cost-effective, plug and play installation that can control thousands of luminaires in less than a second. It is compatible with major climate computers, collects and logs data, sends notifications, provides reports, tracks robots for efficient operation and is customisable for different needs.

A new digital feature from Ellepot connects their integrated propagation system to the Ellepot Live app (available for IOS and Android). The app is designed to make production planning easier.

It translates machine data into easily understood visuals, assists production managers in calculating and ordering production materials and keeping track of daily goals, and also assists machine operators in performing maintenance tasks, ordering certified Ellepot spare parts, and contacting the Ellepot Service Team.

“Everything you need to track and plan out on a day-to-day basis is there on the app, but there is also an Ellepot Live web solution that allows managers further production insights like statistics and other details. It was just as important for us to create a tool that was very convenient …. and we all know that most people have smartphones nowadays (so) Ellepot Live is something you have right at your fingertips,” said Ellepot CEO, Lars Steen Pedersen.

Environment

With more than 25 years of experience with biodegradable film Oerlemans Plastics BV has introduced Bi-OPL biodegradable nursery bags. The basic raw material for this type of film is co-polyester with poly-lactic acid (PLA). Compared to foil based on starch, its major advantages are that it is more stable and degrades more slowly. When the plant is big enough to sell or to plant in the soil, the bag with the crop can simply be planted into the soil.

The Bi-OPL bag degrades completely in the soil due to light, oxygen, temperature and microorganisms in the soil. What remains is just CO2, water and humus. (Ref. EN 17033, EN 13432, OK biodegradable soil)

Bioplasmar of Germany specialises in the production of biodegradable plant pots using regional green waste as raw materials. A new pot has a diameter of 12 cm and a volume of 0.72 litres. It is described as suitable for automated systems and potting machines, as well as for all types of irrigation. It is also mould-free and storage-stable. Once placed in the soil, the pot begins to decompose, providing the plant with the nutrients and promoting plant growth.

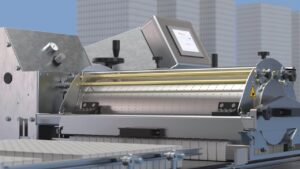

German firm Weber Verpackungen presented a packaging machine for potted plants that it has developed and produced itself for the first time. The machine packs potted flowers and herbs such that productivity increases up to 100% are claimed, and compared with manual hand packing, the same number of pots can be packed in just under half the time. This means that the available staff can be deployed efficiently and employees have time for value-adding tasks.

Use of the pot packer does not incur any investment or rental costs. Billing is on a “pay per pot” basis, which means that the customer only pays a minimal amount when using the system, saving money from day one and improving profitability. Set-up is described as fast and operation is described as simple. The pot packer is ideal for paper sleeves and can also be converted to film sleeves with very little effort.

The pot packer is supplied with two lanes as standard and packs approximately 2,200 pots per hour. The uniform, automatic processing enables a uniform, crease-free appearance of the packed pot plants.

Weed and pest control

Mantis ULV-Sprühgeräte GmbH, manufacturer of Mankar ULV (ultra-low volume) systems and BioMant environmentally friendly hot water weed control, announced a new development based on a successful collaboration with Abemec from the Netherlands using the French agricultural robots from Naïo Technologies. Oz, the smallest robot from Naïo (and some larger robot-models) can now be equipped with a specially designed Mankar ULV-spraying system.

This pressureless ULV system efficiently and economically sprays conventional herbicides, mixtures, and biological herbicides. Different models exist, such as with one or two spray shields and different spray widths, and these machines are ideal for weed control in row crops.

“Managing Director of Mantis ULV-Sprühgeräte GmbHHiske Weissmann said, “The ULV-spraying systems are perfectly suited for economical and targeted spraying of most liquid preparations, as much less product and hardly any water need to be transported compared to conventional spraying technology. They are thus not only an ideal complement for robots but also for drones.”

The AS 1200 rechargeable spray blower from Birchmeier Sprühtechnik AG (Switzerland) has reportedly proved popular in the market and earned awards for its innovative design. The manufacturer recently introduced a flat spray attachment for the spray fan to enable users to apply the product even more efficiently over large areas.

With the new accessory, users can now spray vertically or horizontally – depending on the height or width of the crop. The integrated flat spray nozzle produces a flat spray pattern that can be used to treat specific areas. Applications show that this further improves the wetting of the upper and lower leaf surfaces, and the attachment helps to cultivate crops with even greater efficiency, especially in ornamental plant cultivation and winegrowing.

In addition to the flat spray nozzle and the corresponding lamella attachment, the set also includes a quick-release coupling to easily replace the nozzle. Birchmeier also offers a retrofittable quick-change nozzle system for existing appliances.

The Weedelete® RS hoeing machine is an intra-row weeder for in and between rows of trees. It also considers obstacles and drip hoses into account. To remove weeds, the hoes rotate through the top layer of soil without damage to the crops.

The Weedelete® RS can be attached to a tractor, functioning optimally at low engine power (minimum 30 hp). It also has a levelling effect while following ground contours. Depth control and working width can be adjusted steplessly.

Propagation

With 20 years’ experience in propagation equipment, Korean company Helper Robotech brought its new ultra precision grafting robot (AFGR-800CS) to Essen. It apparently works with melon, cucumber, capsicum and tomato at around 800 pieces per hour with a 95% survival rate. Operating labour requirements are indicated as two (one for stock, one for scions) plus 0.25 assisting.

One of the core elements of sowing seeds in propagation processes is aiming for uniform plant growth. Cells must each hold the right number of seeds; double or missing seeds should simply be avoided. It is also important that the seeds are positioned correctly within the cell. Dutch company Flier Systems offers a range of sowing solutions within different cultivation domains to meet that need.

This year they introduced a new option, a built-in UV light. This UV light disinfects the drum materials and all the seeds that pass through the machine. With this option, you can protect your seeds and materials against micro-organisms and cross-contamination during and in between batches.

At IPM 2024 Flier demonstrated its drum seeder with dibbler fitted with the new UV light. It sows at a higher capacity at a lower speed, contributing to precision and efficiency. The unique moving dibbler ensures a perfect sowing hole whereby the seed is well-centred and positioned at the right depth.

Mobility

Last but not least was a recent Dutch contribution to site mobility from Workstep. The four-wheel electric platform providing mobility for a person and/or transport for small loads presents is a very simple device. It looks like a cross between a removalist’s ‘dolly’ and the now ubiquitous street scooter.

The platform is 900 mm by 640 mm with 300 Wh power that will move up to 500 kg up to 20 km/h and tow up to another 200 kg. The operator stands on the platform and steering and motive control are via a vertical column and handlebars (like the scooters). The operator shares the platform with a load, or tools and cargo can be carried via various optional fitted accessories.

All images supplied by IPM Essen Media