Plastic garden pots – recycle, reuse or use coir and cardboard alternatives?

By Bruce Thompson

Although in major urban centres such as Melbourne, Sydney and Brisbane, garden pot recycling of Plastic Number 5 polypropylene pots is viable, the recycling of plastic garden pots in regional Australia is often out of the question due to the prohibitive freight costs.

With China’s ‘National Sword’ policy bringing a halt to the import of plastics, the 9% of the world’s total plastics that were being recycled is now falling to levels estimated to be as low as 6%.

In response to China’s ‘National Sword’ policy, the Commonwealth Government established its 2025 National Packaging Targets which aims for 100% reusable, recyclable and compostable packaging by 2025; 70% recyclable or compostable plastic packaging by 2025; 50% average recyclable content across all packaging by 2025; and the phase-out of problematic and unnecessary single-use plastic packaging by 2025. It’s an exhausting list to read, let alone implement!

While Germany, with its easy-to-understand Green Dot system which tells everyone what can be recycled, leads the world in recycling 68 % of its waste, Australia sits way down the list at number 21, only four rungs on the recycling ladder above the USA. In 2017-18, just 9.4 % of Australia’s waste, some 320,000 tonnes out of a total 3.4 million tonnes, was recycled. Of that 9.4% amount, 46% (145,700 tonnes) was reprocessed in Australia and 54% (174,300 tonnes) was exported for reprocessing.

On 1st July 2021, the Australian Government banned the export of all mixed plastics which includes Plastic Number 5 garden pots. So, plastic garden pots, together with the other 174,300 plus tonnes of non-exportable recyclables we produce each year, now need to find a new home – a home that is almost certainly going to be landfill.

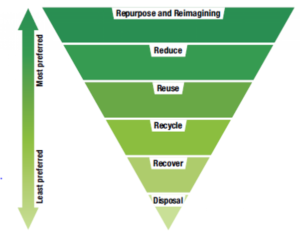

With Plastic Numbers 1 (PETE) and 2 (HDPE) being the only two plastic types materials resource facilities will process for recycling as the ‘National Sword’ policy and ‘mixed plastics export ban’ kick in, there is an urgent need for Australian businesses, regardless of the sector, to re-think how we are using plastics. Horticulturists, regardless of the specific field we work in, are seen by the general public as custodians of the environment, yet we hold tight to practices that aren’t necessarily great for the environment. As an industry, we rely on plastic pots to

ensure longer ‘shelf life’ and transportability of our plants, but as our nation bends over in pain from the swift kick in the guts of ‘National Sword’, market forces and the commercial sourcing of plastic as a resource will awaken new opportunities for old resources, and sustainable resources ‘of the earth, for the earth’.

Plastic pots are made from crude oil, a commodity in short supply. A love for nature and the environment, one would think, should sit diametrically opposed to a plastics industry that necessitates oil being constantly yanked out of Mother Earth to satisfy our insatiable consumptive desires.

With new continents made entirely out of plastic now forming in our oceans, microplastics being found in the air that we breathe and the water we drink, threatening biodiversity and our food supply, it’s time for horticulturists to start cross-pollinating the waste services industry to discover new ways to use old things.

In 2011, Greenlife Industry Australia worked with Garden City Plastics and Sustainability Victoria to enable the recycling of plastic garden pots into one tonne bulker bags, raw granular material that was processed back into new garden pots and other horticultural products at Garden City Plastics’ hi-tech moulding injection plant at Monbulk. Garden City Plastics continues to lead the way with regards to encouraging nurseries to use recycled garden pots and not discard them as landfill.

In October 2020, Greenlife Industry Australia partnered with the Australian Packaging Covenant Organisation (APCO) to establish the PoPPr Program, which is a national recovery program for Polypropylene Plant Packaging. This includes plant pots, trays, tags and stakes. Horticulture Innovation and the Landscape Association works closely with Greenlife Industry Australia to design and implement the collection points for plastic items to be recycled.

The Product Stewardship campaign aims to provide clarity on how plastic garden items can be diverted from landfill. The recent ‘What do we do with the pots’ survey of home gardeners, landscapers, retailers and growers, conducted by SRU Consulting on behalf of Greenlife Industry Australia, aimed to engage stakeholders to provide direction where the industry is heading with plastic pots. The Sustainable Packaging in Horticulture (SPIH) Working Group is another initiative striving to solve the issue of plastic pots.

GT Recycling in Geelong is a player in the market which is also showing leadership, recycling flower crates, garden pots, wheelie bins, bumper bars and other items that would otherwise end up in landfill.

However, for regional council-owned materials resource facilities, the shredding of plastic garden pots into raw material that can be used to make new garden pots is often not viable, due to the process being labour-intensive with someone having to physically separate the pots from other PET and HDPE plastic recyclables, which then feed into a shredder.

So, to future-proof themselves against the rising costs of living in a plastic world, now is the time for nurseries to start looking at more sustainable plant pots. Rubberised natural latex coir pots, such as the Jiffy pot and the growing tube pots offered by Magic Soils Australia, are sustainable pots which the nursery industry

should be seriously considering using. Coir pots promote strong root systems by allowing roots to grow through the pot itself thus reducing transplant shock.

Coir pots are 100% biodegradable and have excellent water holding capacity. They also allow good air penetration, simulating natural plant growing environments. Although plastic shuttle trays for coir tubes are also available through Magic Soils Australia, breathable re-usable terracotta trays, kinder to the planet, could also be used if there was sufficient demand for them. Coir has the added advantage of having a neutral pH.

Mackay Regional Council’s Natural Environment Centre is one nursery which has embraced the coir tubes, using 18,000 tubes in 2020. This number is forecast to increase as China’s ‘National Sword’ starts to impact Commonwealth and State Government policymaking with regards to plastic consumption.

Retail nurseries might also need to look at integrating plants in coir pots into their inventory as the market demands a plastic-free universe. This presents an opportunity to on-sell ceramic, glass and terracotta pots, as well as hanging baskets made from coir string.

As market forces push us closer to the end of the plastic pot era, it’s exciting to think what nurseries might look like ten years from now.

But most significantly, it’s time for Australian horticulturists to cut a new path through the woods (removing only the plastic trees, of course!), so we can plant the sustainable plant-growing seeds for generations of nursery men and women to come.

Shouldn’t a plant that heals Mother Earth, be also kind to Mother Earth in the process of its creation?