Automation is here

By Malcolm Calder –

Automation in nurseries across the country is being adopted. Malcolm Calder from Transplant Systems gives an insight into how savings and efficiencies can be achieved.

In today’s world of production nursery outcomes and requirements, adoption of automation is an absolute necessity. The horticultural industry has, for many decades achieved steady success in the supply of plants throughout Australia. Manual handling, potting, seeding, crafting, irrigation etc has worked. Let’s be honest, tried and true methods have been the norm and, in many cases, continue to be.

Horticulture is about plants grown in a mostly protected cropping environment, that then primarily supplies the agriculture segment which in turn cultivates the plants, on-growing them in open ground. Whether it’s plants for food production, forestry, landscaping, ornamental, flowers, trees and shrubs, all require a level of quality and consistency in order to achieve the final outcome – healthy living stock.

Since 1984, Transplant Systems have contributed to the industry by providing automation. In the early years it was with Lannen open field transplanters and many of those are still in operation today. Over time, the company began migrating into being specialists in protected cropping automation. It’s been quite an amazing journey.

Transplant Systems was instrumental in introducing tray-based, containerised automation which has now become the norm in many nurseries in Australia and New Zealand. The mathematics of volume plant production is simply, how many cells per tray, how many trays per bench, how many benches in the nursery. This has to be carefully calculated in the nursery, case by case, variety by variety.

In today’s environment, wholesale plant nurseries are being challenged to find new ways of increasing production at lower costs.Automation in the nursery is happening across a wide cross section of plant propagation.

What are the drivers? (a) lack of skilled staff (b) increasing cost of energy (c) increasing transport cost (d) disjointed available work hours and lately, adjustments in wage rates and superannuation. The cost of production is a hard barrow to push during buyer-seller price negotiations in a competitive environment. Most of these drivers cannot be side-stepped and nurseries are keen to find new ways of increasing production at lower costs.

Basically, there are two major options which are to sow direct into retail packs, or to sow into plugs and transplant. Another option is to buy plugs from a specialist plug grower, or to sow and grow plugs onsite at the nursery. The economics of the major options depends on the cost of time in the greenhouse space. Direct-sown plants occupy more greenhouse space for a longer time than transplanted plug seedlings. In a warmer climate with simple greenhouses, the daily or weekly cost of the greenhouse space will be low. In cold climates, where higher quality greenhouses need a lot of heating, the weekly cost of greenhouse space will be high.

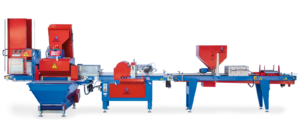

The ways and means to reduce cost can be considered from a wish list that can contribute to the objective, such as greenhouse heating systems, automatic shade screens, humidifying systems, mobile bench systems, irrigation booms, feed and spray injectors, cell tray and plug tray de-stackers and re-stackers, substrate media container filling and seeding lines, plugs trays, transplanters automatic pack and pot labellers, conveyors and automatic sorting devices, robot pallet and stack loaders etc.

Over the next few years we will see some very exciting innovation in the automation space. Developers and suppliers in this realm are investing heavily in R&D to constantly bring reduced costs while improving plant production and growing outcomes.

While larger nurseries have seen the immediate benefit in investing in outcome-based automation and enjoyed a fast return on investment, others are still a little wary of wading in. It’s extremely important that those of us who are supplying the industry understand each individual case, and respectfully offer a matched solution at all levels of requirement and affordability. We respect the many years and past decades of totally manual filling, sowing, growing and harvesting. It still works as good as always. 21st century production nursery operations give us the opportunity to explore automation and see our nurseries and our greenlife improve dramatically. Never fear, automation is here.