High-tech and ‘better mousetraps’

Compiled and edited by John Fitzsimmons

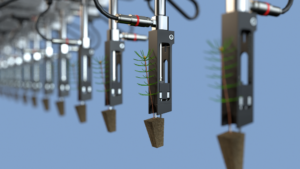

As Dutch startup Cubic Grow BV points out, horticulture is on the verge of a radical transformation with robotics, automation, and autonomous cultivation enhancing efficiency, reducing costs, and optimising product quality. Often, it’s not about inventing the mousetrap but certainly about making a better one.

Initially, robots are taking over repetitive, strenuous, or hazardous tasks such as weeding, pruning, and harvesting. This leads to lower labour costs, less physical strain for workers, and more efficient processes. It also allows for more efficient use of scarce labour resources.

Then there is ‘data-driven optimisation’ with sensors in greenhouses and on plants collecting real-time data on factors such as temperature, humidity, light intensity, and nutrient levels. This data is analysed by computer systems which can then optimise growing conditions.

Precision growing and ‘targeted resource application’ use available technologies to precisely dose individual plants with water, nutrients or pesticides, improving resource use efficiency and reducing environmental impacts.

Ultimately, autonomous systems can control the growing process entirely independently based on data and artificial intelligence (AI). These systems analyse data from sensors and cameras, and then determine the optimal growing conditions – light intensity, temperature, humidity, irrigation, and fertilisation. While these developments may result in demand for manual labour decreasing (job losses increasing), new opportunities emerge for skilled personnel to operate and maintain the new technologies, and demand grows for data analysts who can interpret sensor data. Many of these technologies already exist in other fields and are now being adapted, and applied, to horticulture.

Some of the developing products and technologies recently announced illustrate the possibilities.

Growth chambers

Growth chambers can have a ‘transformative influence’ on plant development. By meticulously adjusting every facet of the growth conditions, environments can be established that optimise growth potential to achieve desired outcomes, for example by neutralising the influence of external weather conditions and traditional day-night light cycles.

In growth chamber environments precision reigns supreme. Meticulous control is particularly critical when the stakes are high, and every young plant demands delicate care, for example when traditional methods prove risky or ineffective. Hygiene is also vital. Achieving the best results hinges on a methodical approach to cleanliness. Through the implementation of appropriate air filtration, sterilisation, precise air pressure control within the facility and state-of-the-art door technologies, “an immaculate laboratory environment can be upheld”.

Maximising useable plants

When delivering flower seeds, it is very important that the customer knows what percentage of the seeds gives usable plants. Until now this was determined manually and was subjective and labour intensive. However, the new GA-box from AgriData Innovations (ADI) automates the process reliably with the definition of ‘useable’ now consistent and fully objective. The operator inserts a tray and the machine takes a picture. Moments later an image of the tray full of red crosses, and red, orange and green circles appears on a screen. A cross means an empty cell and a red circle is a plant the machine rejects. Orange and green circles count as ‘usable’, which are plants that will grow out into a viable plant. The GA-box is being used with cyclamen and is being tested for Primula acaulis.

With Seedling Scan Pro, germination analysis and seedling counts are automated. Trays are digitally counted in a matter of seconds compared to minutes of manual counting. Human subjectivity is eliminated and the count, plus an image, is stored automatically to build a database.

Smart-eyes

Digital Innovations’ Smart-Eyes take photos of a crop that are then analysed for important metrics – length, leaf area, number of buds, flower diameter and number of fruits. It also scouts for pests and diseases in the crop such as discoloration, damage or holes in the leaves. The collected metrics are used for harvest forecasts, optimisation of cultivation strategies, and management of pests and diseases. Smart-eyes can be used on tomatoes, lettuce, phalaenopsis, chrysanthemum, other cut flowers, and pot and bedding plants.

Data-driven chrysanthemum cultivation

Dutch grower Leen Middelburg Chrysanthemums is now complementing human growing knowledge with reliable data. At Maasdijk and other sites they are busy monitoring the crop using ADI’s vision technology. The data is then integrated into Delphy’s growth models. By understanding the chrysanthemums better, they can make better cultivation decisions. Knowledge of the crop is essential and technology can help with that. Middelburg started searching for good camera technology to learn more about the chrysanthemums a few years ago, the idea being that the camera had to be mobile and not fixed in one position. “Chrysanthemum cultivation is very dynamic. We harvest and plant every day, so the crop is different every day,” the grower explained.

(*Adapted from a report in Versnellen Groene Digitalisering Glastuinbouw by Mario van Vliet. Translated from Dutch)

Knowledge discovery

Other chrysanthemum growers at Zentoo were looking for a similar solution. A steering group was started with breeder Deliflor Chrysanten, fertiliser supplier Van Iperen, and Delphy, to explore how data-driven chrysanthemum cultivation could be promoted. One of its projects is the use of cameras to measure the crop. This involves collaboration with AgriData Innovations, the Delft-based company that initially started with drones but has been focused on camera technology and computer vision software for crop monitoring for the last three years. Drones are small and light – ideal but there are challenges with battery life and achieving stable photo quality. Especially with data collection using cameras on a large scale, good photo quality is needed and preferably as quickly as possible (so) drones are no longer used by the Zentoo growers. A method was sought where a camera could quickly take stable pictures. Cameras were then fitted on spraying booms which drive over the chrysanthemum crop daily; that ‘robot’ is an excellent host for a camera. The spraying boom was first fitted with one camera capturing one bed of chrysanthemums. Currently there are two cameras on it, capturing two beds. They’re now moving towards six cameras for six beds. These cameras use computer vision software to measure the length, leaves, and buds of the crop. This information is then automatically imported into the QMS, the cultivation management system that Delphy developed for a large number of crops, including chrysanthemums. QMS Chrysanthemum determines how production and quality can be maximised. It uses data regarding weather, lighting, cultivation strategy, and processes that into growth models for the respective crop. The data in the QMS has to be reliable and consistent so the first step was to validate the data from the cameras. The data provided by the cameras is not the only input for the QMS; climate control systems and information about the variety are also part of the calculations.

Tuning up LED lighting

Vertically Urban is a horticultural lighting specialist of LED lighting solutions, designing and manufacturing products in the United Kingdom with the highest photon-yielding LEDs available. It recently released its latest horticultural lighting innovations: Horti-Blaze Tunable and Odyssey Tunable, designed specifically for vertical farms and glasshouses. These products incorporate advanced technology that revolutionises the way growers control light spectra, providing unparalleled customisation tailored to each crop’s unique needs.

Horti-Blaze Tunable is engineered for vertical farms and other space-constrained growing environments. With its wide beam angle and high-power output, this luminaire minimises the number of fixtures required for optimum coverage. An innovative addressable ‘data-over-power’ system allows for individual luminaire control via a single cable connection, simplifying installation compared to traditional systems.

Odyssey Tunable combines advanced dynamic spectrum technology with the power of a ‘high bay’ top light, offering versatility in greenhouse environments of any size. Unlike traditional fixed spectrum lighting systems, tunable lighting allows growers to tailor the light spectrum to the specific needs of different plants. Furthermore, tunable lighting enables the implementation of sophisticated lighting schedules, adjusting the light spectrum and intensity throughout the day, and the plant’s life cycle. This agile energy management not only improves profitability but also promotes sustainability by reducing overall energy consumption. (*From original report by Neil Arden)

Green Tech innovations

As usual, a significant number of innovations were announced in various categories at the recent Green Tech in the Netherlands. Some were new concepts entirely, and some were advanced new tools for horticulture and agriculture.

- Smart Sleever from Bosman Van Zaal: Category: Concept Award – The most promising new idea. New in the world June 2024. Developed with Vilosa, SV.CO and KP Holland, the Smart Sleever fills an automation gap, sleeving small batches of potted plants. The unit accommodates plastic and sustainable paper sleeves. With gentle plant insertion it eliminates the standard dropping. It is described as compact and easily integrated for flexible and gentle plant handling.

- FE3owlet ECblue with ZAplus greenhouse fan from ZIEHL-ABEGG Benelux BV: Category: Innovation Award – The most revolutionising idea. New in the world June 2024. The FE3owlet axial fan combines a biomimetically optimised blade with an additional rippled leading edge. The result is a blade with an adjustable blade angle, a high degree of flexibility due to a fully speed-controlled volume flow rate, and superior efficiency for application in greenhouses. It has a vibration sensor, NFC manual, active PFC, flexible connection M12, and bluetooth.

- Drone Pest & Disease Detection from Corvus Drones BV: Category: Concept Award – The most promising new idea. New in the world January 2024. Corvus Drones Anomaly Detection identifies plant anomalies like tip burn, leaf discolouration, yellowing and canopy coverage. The drone monitors the crop 100% automatically from start to reporting (interactive or SMS alert). Validated applications are young plants (vegetables and soft fruit), annuals, pot plants and roses. These drones are now used by growers in over 10 countries.

- Roll’N Grow from BioTherm: Category: Innovation Award – The most revolutionising idea. New in the world 2023. Roll’N Grow makes it easy to apply root zone heating to growing beds or benches. Like a carpet, it rolls out over growing surfaces to supply growth-enhancing heat in less time than previously possible. It can be customised to fit desired dimensions.

- LDC 101 Starch Based Greenhouse Shading Coating from Lumiforte. Category: Innovation Award – The most revolutionising idea. New in the world June 2024. LDC 101 Starch Based Greenhouse Shading Coating against excess sunlight and heat is a self-degradable liquid shading coating, powered by a modified starch technology, which provides up to four months of wear resistance. As time progresses, the coating naturally degrades, maintaining its environmentally friendly characteristics and is suitable for all types of greenhouses.

- FRAVEBOT Scout from FRAVEBOT sro: Category: Innovation Award – The most revolutionising idea. New in the world 2023. FRAVEBOT is Czechia-based startup. Its autonomous robots periodically check every plant in the greenhouse. The grower is promptly notified of any issues with their plants by the system, which automatically identifies patterns in the daily data. The system is also designed to forecast the yield based on each plant’s past data.

- Auxin from Royal Brinkman: Category: Innovation Award – The most revolutionising idea. New in the world April 2024. Auxin is a unique digital platform for data analysis and control of hardware, such as drones. The system is the collection source of crop measurements and uses AI to relate the data. The combination of independent databases, supplemented by domain knowledge from practice, leads to new insights and uncoloured and professional advice for the grower.

- Harvest Wall 2.0 Vertigation System from Harvest Today: Category: Innovation Award – The most revolutionising idea. New in the world September 2024. The system is a self-watering vertical grow wall for produce. Its patented design features interlocking tiles that allow water and nutrients to saturate 720 plants rapidly by cascading down vertigation channels. A blend of organic and tech, the Harvest Wall 2.0 uses organic growing media allowing the plants to establish microbiomes through healthy root systems.

- High Speed Grafter from ISO: Category: Innovation Award – The most revolutionising idea. New in the world July 2024. ISO automates the craft of grafting, claiming to be the first in the world to develop a fully automatic grafting machine without needing manual labour and with high consistency. The High Speed Grafter combines Vision AI technology for automatic quality selection and robots to graft perfectly at speeds up to 4000 plants per hour.

All images supplied by GreenTech